Services

What we provide

CROME PLATING:

We provide advanced chrome plating technologies such as "Porous Krome" and "hard chrome" plating for different diesel engine components & various other parts of hydraulics. Components are chrome plated with hardness up to 60-65 HRC and are super finish to achieve required surface finish value. Porous chrome plating processes provides better lubrication and lower wear rate resulting in longer service life of Diesel Engine Components, Cylinder Components. Plating process followed has been approved by American Bureau Society (ABS) and tested at NABL approved laboratory for Salt Bath Test, Chrome peel off test, Hardness Test.

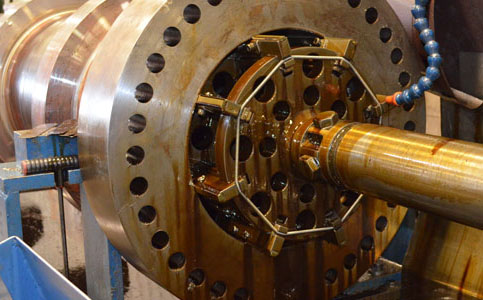

HONING :

Honing can be done to a very close tolerance and with high surface finish value. With their self-aligning mechanism we are capable of maintaining the concentricity and circularity within 5 to 10 microns. Our valued customer bears testimony to our competence of our two Gehring make German vertical honing machines. Jobs with bore diameter up to 1200mm and length in excess of 8 meters can easily be honed on our vertical honing machines.

GRINDING AND POLISHING :

In house three nos Friedrich Schmaltz-German make cylindrical grinding machines equipped with CNC controlled, cylindrical cum crank-shaft grinding facility. We ensure that jobs are immediately undertaken to precision grinding and are super-finished with accuracy of 0.001mm that is 01 micron. Jobs with diameters up to 1250 mm ad lengths in excess of 11 meters are easily accommodated.